fishing bag

The main application field of the fishing bag

The fishing bag is mainly used for storing fishing tackle, such as lures, hooks, lines, reels, and other fishing accessories. It is also used to store fish that have been caught, as well as to carry food and drinks for a day of fishing.

What is a fishing bag?

A fishing bag is a type of bag specifically designed to store and transport fishing gear. It typically features multiple compartments and pockets for storing items such as lures, tackle, line, and other fishing accessories. Fishing bags are usually made from waterproof materials and are designed to be durable and lightweight.

Why do we need fishing bag?

Fishing bags are essential for any angler, as they provide a convenient way to store and transport all of your fishing gear. Fishing bags are designed to be durable and waterproof, so they can protect your gear from the elements. They also provide plenty of storage space for tackle, lures, bait, and other fishing accessories. Fishing bags are also great for organizing your gear, so you can easily find what you need when you’re out on the water.

When did humans start using fishing bag?

The use of fishing bags dates back to ancient times, with evidence of woven fishing bags found in archaeological sites from the Neolithic period.

History of fishing bag development

The history of fishing bags dates back to the early 1800s when fishermen began using canvas bags to store their fishing gear. These bags were typically made of heavy canvas and had a drawstring closure. Over time, the design of fishing bags evolved to include features such as waterproofing, adjustable straps, and pockets for storing tackle and other items. In the 1950s, nylon and other synthetic materials began to be used in the construction of fishing bags, making them lighter and more durable. Today, fishing bags come in a variety of styles and materials, including waterproof fabrics, insulated compartments, and specialized pockets for storing tackle and other items.

The development trend of the fishing bag industry

The fishing bag industry is expected to experience significant growth in the coming years. This is due to the increasing popularity of fishing as a recreational activity, as well as the growing demand for specialized fishing bags that are designed to meet the needs of anglers. In addition, technological advancements in the industry are expected to drive further growth. This includes the development of more durable and lightweight materials, as well as the introduction of new features such as waterproofing and insulation. Furthermore, the increasing availability of online shopping options is expected to further boost the industry.

What are the classifications of fishing bag?

1. Tackle Bags: These bags are designed to store and organize fishing tackle, such as lures, hooks, line, and other fishing accessories.

2. Backpack Fishing Bags: These bags are designed to be worn on the back and are great for anglers who need to carry a lot of gear.

3. Chest Fishing Bags: These bags are designed to be worn around the chest and are great for anglers who need to carry a few items.

4. Waist Fishing Bags: These bags are designed to be worn around the waist and are great for anglers who need to carry a few items.

5. Boat Fishing Bags: These bags are designed to be used on boats and are great for anglers who need to carry a lot of gear.

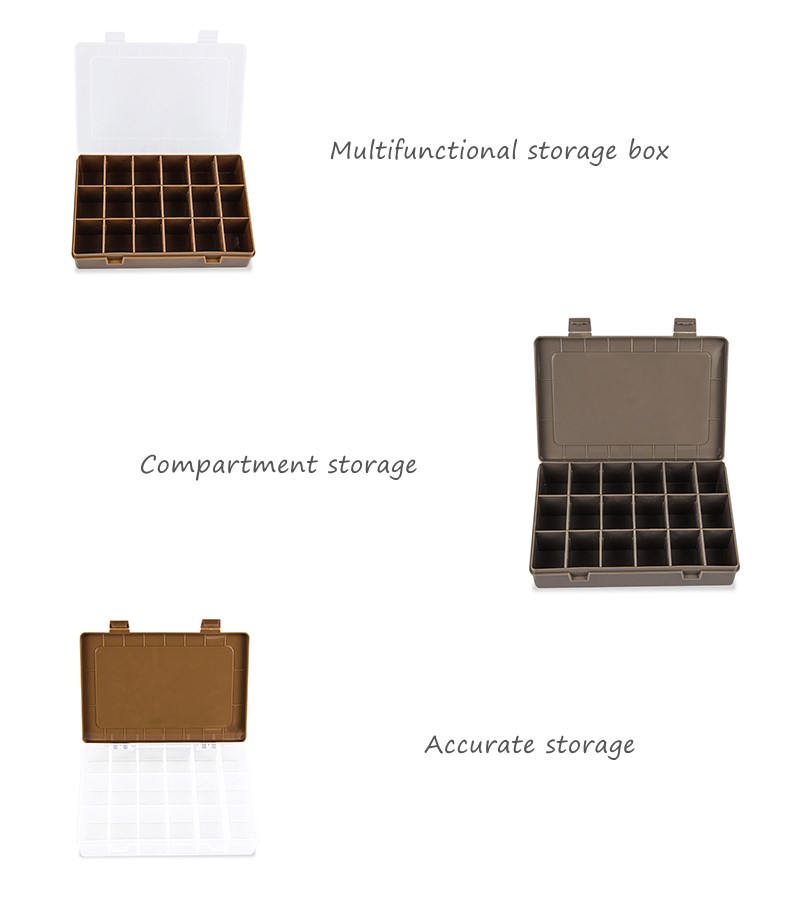

6. Tackle Boxes: These boxes are designed to store and organize fishing tackle, such as lures, hooks, line, and other fishing accessories.

Inventor of the fishing bag

The fishing bag was invented by the American outdoorsman and entrepreneur, William C. "Bill" Mason, in the early 1950s. Mason was an avid fisherman and outdoorsman who wanted to make fishing more convenient and comfortable. He designed a bag that could hold all of his fishing gear, including tackle, bait, and lures, and keep it organized and easily accessible. The bag was made of heavy-duty canvas and had several pockets and compartments to store different items. Mason's invention revolutionized the way people fished and is still used today.

What is the fishing bag manufacturer?

There are many fishing bag manufacturers, including Simms Fishing Products, Fishpond, Orvis, Patagonia, and Rapala.

How to choose the fishing bag manufacturer with the best quality?

1. Research the manufacturer's reputation: Check online reviews and customer feedback to get an idea of the manufacturer's quality and customer service.

2. Ask for samples: Ask the manufacturer to provide samples of their products so you can inspect the quality and craftsmanship.

3. Check the materials used: Make sure the manufacturer is using high-quality materials that are durable and long-lasting.

4. Ask about warranties: Ask the manufacturer about their warranty policies and what kind of coverage they offer.

5. Compare prices: Compare prices between different manufacturers to make sure you're getting the best deal.

What material is suitable for fishing bag

Fishing bags are typically made from waterproof materials such as nylon, polyester, or canvas. These materials are lightweight, durable, and water-resistant, making them ideal for carrying fishing gear. Some fishing bags also feature waterproof zippers and pockets to keep your gear dry and secure.

What products can fishing bag manufacturers produce?

Fishing bag manufacturers can produce a variety of products, including tackle bags, backpacks, duffel bags, dry bags, and coolers. They can also produce specialized bags for specific types of fishing, such as fly fishing, ice fishing, and kayak fishing.

What are the specific requirements of fishing bag manufacturer?

1. Ability to produce a variety of sizes and styles of fishing bags.

2. Knowledge of the latest trends in fishing bag design.

3. Ability to source quality materials for the bags.

4. Ability to customize bags to meet customer needs.

5. Knowledge of the fishing industry and the needs of anglers.

6. Ability to provide a high level of customer service.

7. Ability to meet tight deadlines.

8. Ability to work with a variety of fabrics and materials.

9. Knowledge of the latest safety regulations and standards.

10. Ability to provide a warranty on the bags.

How can fishing bag manufacturers improve production quality?

1. Invest in high-quality materials: Investing in high-quality materials is essential for producing quality fishing bags. Choose materials that are durable, waterproof, and lightweight.

2. Utilize quality control measures: Quality control measures should be implemented throughout the production process to ensure that all bags meet the highest standards.

3. Invest in modern machinery: Investing in modern machinery can help to improve production efficiency and reduce the risk of errors.

4. Train employees: Training employees on proper production techniques can help to ensure that all bags are produced to the highest standards.

5. Implement a quality assurance system: Implementing a quality assurance system can help to identify and address any issues that may arise during the production process.

Production scale and production capacity of fishing bag manufacturer

The production scale and production capacity of a fishing bag manufacturer will depend on the size of the factory, the number of employees, and the type of machinery and equipment used. Generally speaking, a larger factory with more employees and more advanced machinery and equipment will have a larger production scale and production capacity.

What is the maintenance content of the fishing bag manufacturer's production equipment?

1. Regularly check the lubrication of the equipment and add lubricating oil in time.

2. Regularly check the wear of the parts and replace the worn parts in time.

3. Regularly check the electrical system of the equipment and replace the damaged parts in time.

4. Regularly clean the equipment and keep the equipment clean and tidy.

5. Regularly check the tightness of the screws and bolts of the equipment and tighten them in time.

6. Regularly check the temperature of the equipment and adjust the temperature in time.

7. Regularly check the operation of the equipment and adjust the operation in time.

fishing bag manufacturer produce equipment, how to improve equipment management efficiency

1. Establish a clear equipment management system: Establish a clear equipment management system, including the management of equipment purchase, use, maintenance, and disposal.

2. Establish an equipment inventory system: Establish an inventory system to track the number of equipment, their location, and their condition.

3. Establish a preventive maintenance system: Establish a preventive maintenance system to ensure that all equipment is regularly inspected and maintained.

4. Establish a tracking system: Establish a tracking system to monitor the use of equipment and ensure that it is used properly and safely.

5. Establish a training program: Establish a training program to ensure that all personnel are properly trained in the use of equipment.

6. Establish a safety program: Establish a safety program to ensure that all personnel are aware of the safety risks associated with the use of equipment.

7. Establish a reporting system: Establish a reporting system to ensure that any issues with equipment are reported and addressed promptly.

What production equipment do fishing bag manufacturer need?

1. Sewing machines: These are used to stitch together the various components of the fishing bag.

2. Cutting machines: These are used to cut the fabric and other materials used in the bag.

3. Heat press machines: These are used to apply logos and other designs to the bag.

4. Embroidery machines: These are used to add embroidery to the bag.

5. Finishing machines: These are used to add zippers, buttons, and other finishing touches to the bag.

6. Quality control equipment: This is used to ensure that the bags meet the required standards.

Advantages and development direction of fishing bag manufacturers

1. Advantages: Fishing bag manufacturers have a wide range of products, including fishing bags, fishing backpacks, fishing tackle bags, fishing waist bags, fishing tool bags, etc. The products are made of high-quality materials, which are waterproof, wear-resistant and durable.

2. Development direction: Fishing bag manufacturers should continue to develop new products to meet the needs of different customers. At the same time, they should also pay attention to the quality of the products, and strive to provide customers with high-quality and cost-effective products.

fishing bag manufacturer production technology coverage

Fishing bag manufacturers typically use a variety of production technologies to create their products. These technologies include cutting, sewing, printing, and finishing. Cutting involves using a variety of tools to cut the fabric into the desired shape and size. Sewing involves using a sewing machine to stitch the fabric together. Printing involves using a variety of techniques to add logos, designs, and other graphics to the fabric. Finishing involves using a variety of techniques to add waterproofing, UV protection, and other features to the fabric.

Analysis on the layout of fishing bag manufacturer in China's industrial chain

China's fishing bag industry is a relatively mature industry, and the industrial chain of fishing bag manufacturers is relatively complete. The industrial chain of fishing bag manufacturers in China can be divided into four parts: raw material suppliers, fishing bag manufacturers, distributors, and end consumers.

Raw material suppliers: Raw material suppliers are the upstream of the fishing bag industry chain. They provide the necessary raw materials for the production of fishing bags, such as fabrics, zippers, buckles, etc.

Fishing bag manufacturers: Fishing bag manufacturers are the core of the fishing bag industry chain. They are responsible for the production of fishing bags, including design, production, and sales.

Distributors: Distributors are the middlemen of the fishing bag industry chain. They are responsible for the distribution of fishing bags to the end consumers.

End consumers: End consumers are the downstream of the fishing bag industry chain. They are the ultimate users of fishing bags.

In conclusion, the industrial chain of fishing bag manufacturers in China is relatively complete, and the four parts of the chain are closely connected.

fishing bag manufacturer production line

A fishing bag manufacturer production line typically consists of several machines and processes. These include cutting machines, sewing machines, fabric printing machines, and other specialized equipment. The production line also includes quality control processes, such as inspecting the bags for defects and ensuring that the bags meet the customer’s specifications. The production line also includes packaging and shipping processes.

Matters needing attention in the development of raw material supply chain for fishing bag manufacturer

1. Establish a reliable raw material supply chain: It is important to establish a reliable raw material supply chain for a fishing bag manufacturer. This includes finding reliable suppliers, negotiating favorable terms, and ensuring that the raw materials are of good quality.

2. Monitor the quality of raw materials: Quality control is essential for any fishing bag manufacturer. It is important to monitor the quality of raw materials to ensure that they meet the required standards.

3. Develop a cost-effective supply chain: It is important to develop a cost-effective supply chain for a fishing bag manufacturer. This includes finding the most cost-effective suppliers, negotiating favorable terms, and ensuring that the raw materials are of good quality.

4. Establish a sustainable supply chain: It is important to establish a sustainable supply chain for a fishing bag manufacturer. This includes finding suppliers who use sustainable practices, such as using renewable energy sources and minimizing waste.

5. Develop a reliable logistics system: It is important to develop a reliable logistics system for a fishing bag manufacturer. This includes finding reliable carriers, negotiating favorable terms, and ensuring that the raw materials are delivered on time.

Detailed explanation of the production process of fishing bag manufacturer

1. Design: The first step in the production process of a fishing bag manufacturer is to design the bag. This involves creating a prototype of the bag, which includes the size, shape, and features of the bag. The design should also include the materials that will be used to construct the bag.

2. Fabrication: Once the design is finalized, the fabric for the bag is cut and sewn together. This is done using specialized machines and tools. The fabric is then inspected for quality and durability.

3. Finishing: After the fabric is sewn together, the bag is finished with various treatments such as waterproofing, UV protection, and other treatments.

4. Assembly: The bag is then assembled, which includes attaching the straps, pockets, and other features.

5. Quality Control: The bag is then inspected for quality and durability.

6. Packaging: The bag is then packaged for shipping.

7. Shipping: The bag is then shipped to the customer.

Production profit of fishing bag manufacturer

The profit of a fishing bag manufacturer depends on a variety of factors, including the cost of materials, labor, overhead, and marketing. The manufacturer's profit is calculated by subtracting all of these costs from the total revenue generated from the sale of the fishing bags. The profit margin of a fishing bag manufacturer can vary greatly depending on the quality of the product, the demand for the product, and the pricing strategy of the manufacturer.

Covered content of the fishing bag manufacturer's production process

1. Design: The fishing bag manufacturer will first design the bag based on customer specifications. This includes selecting the materials, colors, and features of the bag.

2. Cutting: The manufacturer will then cut the materials to the desired size and shape.

3. Sewing: The manufacturer will then sew the pieces together to create the bag.

4. Finishing: The manufacturer will then add any additional features such as pockets, straps, and zippers.

5. Quality Control: The manufacturer will then inspect the bag for any defects or flaws.

6. Packaging: The manufacturer will then package the bag for shipping.

fishing bag manufacturer need to meet the following environmental protection requirements

1. Use eco-friendly materials in the production of fishing bags, such as recycled fabrics, organic cotton, and other sustainable materials.

2. Implement energy-saving measures in the production process, such as using renewable energy sources and reducing energy consumption.

3. Reduce water consumption and wastewater discharge in the production process.

4. Adopt waste reduction and recycling measures in the production process.

5. Comply with local environmental regulations and standards.

6. Implement a comprehensive environmental management system.

7. Educate employees on environmental protection and sustainability.

Production process management of fishing bag manufacturers

1. Design: The design process of fishing bag manufacturers begins with the customer's requirements. The design team will create a design based on the customer's needs and preferences. The design team will then create a prototype of the bag and present it to the customer for approval.

2. Production: Once the design is approved, the production team will begin the process of manufacturing the bag. This includes cutting the fabric, sewing the pieces together, and adding any necessary hardware. The production team will also inspect the bag for quality assurance.

3. Quality Control: Quality control is an important part of the production process. The quality control team will inspect the bag for any defects or flaws. If any are found, the bag will be sent back to the production team for correction.

4. Packaging: Once the bag has been inspected and approved, it will be packaged for shipping. The packaging team will ensure that the bag is properly protected and labeled for shipping.

5. Shipping: The shipping team will then arrange for the bag to be shipped to the customer. The shipping team will also track the shipment and provide updates to the customer.

How do fishing bag manufacturer solve the application of new technologies

Fishing bag manufacturers can use new technologies to improve their products in a variety of ways. For example, they can use advanced materials to make their bags more durable and waterproof. They can also use new technologies to create innovative designs that are more comfortable and functional. Additionally, they can use new technologies to create more efficient production processes, which can help them reduce costs and increase profits. Finally, they can use new technologies to create better customer experiences, such as providing online ordering and tracking systems.

How can fishing bag manufacturer improve production efficiency

1. Invest in Automation: Investing in automation can help fishing bag manufacturers increase production efficiency by reducing the amount of manual labor required. Automation can also help reduce errors and improve product quality.

2. Streamline Processes: Streamlining processes can help fishing bag manufacturers reduce waste and increase efficiency. This can include streamlining the production process, reducing the number of steps required to complete a task, and eliminating unnecessary steps.

3. Invest in Quality Control: Quality control is essential for any manufacturing process. Investing in quality control measures can help fishing bag manufacturers ensure that their products meet customer expectations and reduce the amount of time spent on rework and repairs.

4. Utilize Lean Manufacturing: Lean manufacturing is a set of principles and practices that focus on eliminating waste and improving efficiency. Utilizing lean manufacturing principles can help fishing bag manufacturers reduce costs and increase production efficiency.

5. Invest in Training: Investing in training can help fishing bag manufacturers ensure that their employees are knowledgeable and skilled in the production process. This can help reduce errors and increase efficiency.

How to improve the manufacturing process of fishing bag manufacturer

1. Invest in Automation: Investing in automation can help streamline the manufacturing process and reduce labor costs. Automation can also help reduce errors and improve quality control.

2. Implement Lean Manufacturing: Lean manufacturing is a process that focuses on eliminating waste and improving efficiency. Implementing lean manufacturing can help reduce costs and improve the overall quality of the product.

3. Invest in Quality Control: Quality control is essential for any manufacturing process. Investing in quality control measures can help ensure that the product meets customer expectations.

4. Invest in Training: Training employees on the latest manufacturing techniques can help improve the overall efficiency of the process.

5. Invest in Technology: Investing in the latest technology can help improve the speed and accuracy of the manufacturing process.

6. Improve Communication: Improving communication between departments can help ensure that everyone is on the same page and working towards the same goal.

7. Invest in Research and Development: Investing in research and development can help improve the overall quality of the product and help the company stay ahead of the competition.

Instructions for cooperation with fishing bag manufacturer

1. Establish a clear timeline: Before beginning any collaboration with a fishing bag manufacturer, it is important to establish a timeline for the project. This timeline should include the expected completion date, as well as any milestones that need to be met along the way.

2. Set expectations: It is important to set expectations for the project before beginning any collaboration. This includes expectations for quality, cost, and delivery time.

3. Communicate regularly: Regular communication is essential for successful collaboration. This includes both verbal and written communication, as well as regular meetings to discuss progress and any issues that may arise.

4. Provide feedback: Providing feedback to the manufacturer is essential for successful collaboration. This feedback should be both positive and constructive, and should be used to help the manufacturer improve their products and services.

5. Follow up: Following up with the manufacturer is important to ensure that the project is progressing as expected. This includes checking in on the progress of the project, as well as any issues that may have arisen.

What are the services of fishing bag manufacturer?

Fishing bag manufacturers typically provide a range of services, including custom design, prototyping, production, and delivery. They can also provide additional services such as logo and branding, product testing, and quality assurance. Additionally, some fishing bag manufacturers may offer repair and maintenance services, as well as product customization.

How do fishing bag manufacturer implement new product development

1. Research: Fishing bag manufacturers should conduct market research to identify customer needs and preferences. This can be done through surveys, focus groups, interviews, and other methods.

2. Design: Fishing bag manufacturers should create a design for the new product that meets customer needs and preferences. This should include features, materials, and other specifications.

3. Prototype: Fishing bag manufacturers should create a prototype of the new product to test its functionality and durability.

4. Testing: Fishing bag manufacturers should test the prototype to ensure it meets customer needs and preferences. This can be done through field testing, laboratory testing, and other methods.

5. Production: Fishing bag manufacturers should produce the new product in accordance with the design and testing results.

6. Marketing: Fishing bag manufacturers should create a marketing plan to promote the new product. This should include advertising, public relations, and other methods.

How do fishing bag manufacturer establish a sound supply chain management

1. Establish a clear supply chain strategy: A fishing bag manufacturer should develop a clear supply chain strategy that outlines the company’s goals and objectives. This strategy should include the company’s desired level of customer service, cost structure, and supplier selection criteria.

2. Develop a supplier selection process: A fishing bag manufacturer should develop a supplier selection process that evaluates potential suppliers based on criteria such as quality, cost, delivery, and service.

3. Establish a supplier relationship management system: A fishing bag manufacturer should establish a supplier relationship management system that allows the company to track and manage supplier performance. This system should include metrics such as on-time delivery, quality, and cost.

4. Implement a demand forecasting system: A fishing bag manufacturer should implement a demand forecasting system that allows the company to accurately predict customer demand. This system should include metrics such as historical sales data, customer feedback, and market trends.

fishing bag manufacturer service and quality system

A fishing bag manufacturer should have a comprehensive service and quality system in place to ensure that their products meet the highest standards of quality and customer satisfaction. This system should include a customer service team that is available to answer questions and provide assistance with product selection, ordering, and delivery. The manufacturer should also have a quality assurance team that inspects and tests all products before they are shipped to customers. Additionally, the manufacturer should have a system in place to track customer feedback and complaints, and to address any issues that arise. Finally, the manufacturer should have a system for tracking and analyzing customer data to identify areas of improvement and to ensure that their products are meeting customer expectations.

Customer group and service level of fishing bag manufacturer

The customer group for a fishing bag manufacturer would likely include anglers, fishing guides, and outdoor enthusiasts. The service level would depend on the specific manufacturer, but could include custom orders, product warranties, and customer service support.

How to improve the quality of fishing bag manufacturers

1. Invest in high-quality materials: Investing in high-quality materials is one of the best ways to improve the quality of fishing bag manufacturers. Quality materials will ensure that the bags are durable and long-lasting.

2. Utilize advanced technology: Utilizing advanced technology can help fishing bag manufacturers produce higher quality products. This includes using automated machines to cut and sew the bags, as well as using computer-aided design (CAD) software to create the patterns.

3. Hire experienced staff: Hiring experienced staff is essential for producing high-quality fishing bags. Experienced staff will be able to identify potential problems and make sure that the bags are made to the highest standards.

4. Implement quality control measures: Quality control measures should be implemented to ensure that the bags are made to the highest standards. This includes inspecting the bags for defects and ensuring that the materials used are of the highest quality.

5. Provide customer service: Providing excellent customer service is essential for fishing bag manufacturers. This includes responding to customer inquiries in a timely manner and providing helpful advice and support.

R&D direction of fishing bag manufacturer industry

1. Developing new materials: Fishing bag manufacturers should continue to explore new materials that are lightweight, durable, and waterproof.

2. Improving design: Fishing bag manufacturers should focus on improving the design of their products to make them more ergonomic and comfortable to use.

3. Enhancing functionality: Fishing bag manufacturers should strive to make their products more functional by adding features such as pockets, straps, and compartments.

4. Increasing sustainability: Fishing bag manufacturers should focus on developing products that are more sustainable and eco-friendly.

5. Enhancing safety: Fishing bag manufacturers should focus on developing products that are safer for the user and the environment.

6. Improving customer service: Fishing bag manufacturers should strive to provide better customer service and support to their customers.

After-sales compensation terms for fishing bag manufacturer

1. Warranty: The fishing bag manufacturer should provide a warranty period of at least one year from the date of purchase. During this period, any defects in material or workmanship should be repaired or replaced free of charge.

2. Refunds: If the customer is not satisfied with the product, the fishing bag manufacturer should offer a full refund within 30 days of purchase.

3. Repairs: The fishing bag manufacturer should offer free repairs for any defects in material or workmanship within the warranty period.

4. Replacement Parts: The fishing bag manufacturer should provide replacement parts for any defective parts within the warranty period.

5. Customer Service: The fishing bag manufacturer should provide prompt and courteous customer service to address any customer inquiries or complaints.

What services are included in the fishing bag manufacturer's after-sales service?

The after-sales service of a fishing bag manufacturer typically includes product warranty, repair and replacement services, customer support, and product returns. Additionally, some manufacturers may offer additional services such as product customization, product training, and product maintenance.

How do fishing bag manufacturer establish their own fishing bag dealer channels

1. Develop a comprehensive marketing strategy: Fishing bag manufacturers should develop a comprehensive marketing strategy that includes both online and offline marketing tactics. This should include creating a website, developing a social media presence, and creating a network of fishing bag dealers.

2. Reach out to potential dealers: Fishing bag manufacturers should reach out to potential dealers by attending trade shows, networking events, and other industry events. They should also contact local fishing stores and other retailers to inquire about becoming a dealer.

3. Offer incentives: Fishing bag manufacturers should offer incentives to dealers to encourage them to carry their products. This could include discounts, free shipping, or other promotional offers.

4. Provide support: Fishing bag manufacturers should provide support to their dealers by offering training, technical assistance, and other resources. This will help ensure that dealers are knowledgeable about the products and can provide the best customer service.

5. Monitor performance: Fishing bag manufacturers should monitor the performance of their dealers to ensure that they are meeting sales goals and providing quality customer service. This will help ensure that the dealers are successful and that the manufacturer is getting the most out of their investment.

fishing bag manufacturer are more worthy of cooperation if they have patents

Yes, fishing bag manufacturers with patents are more worthy of cooperation because they have the legal right to protect their products from being copied or used without permission. Patents also give manufacturers the ability to charge higher prices for their products, as they can prove that their products are unique and of higher quality than those of their competitors.

Product quality control of fishing bag manufacturer

1. Establish a quality control system: The first step in quality control is to establish a quality control system. This system should include a set of procedures and processes that are used to ensure that the products meet the required standards.

2. Inspect raw materials: Before production begins, the raw materials should be inspected to ensure that they meet the required standards. This includes checking for any defects or impurities.

3. Monitor production process: During the production process, the manufacturer should monitor the process to ensure that the products are being made according to the required standards.

4. Test finished products: After the production process is complete, the finished products should be tested to ensure that they meet the required standards.

5. Track customer feedback: The manufacturer should track customer feedback to identify any issues with the products. This can help the manufacturer identify any areas that need to be improved.

The international production mode adopted by fishing bag manufacturers

Fishing bag manufacturers often adopt an international production mode, which involves the production of fishing bags in different countries. This mode of production allows manufacturers to take advantage of the lower labor costs and other resources available in different countries. This mode of production also allows manufacturers to access a wider range of materials and components, as well as access to a larger customer base. Additionally, this mode of production allows manufacturers to reduce their production costs and increase their profits.

What is fishing bag design?

Fishing bag design is the process of creating a bag specifically designed for carrying fishing gear. This includes designing the shape, size, and features of the bag to best suit the needs of the user. The design should also consider the type of fishing being done, the environment, and the user’s preferences. Fishing bags can be made from a variety of materials, including canvas, nylon, and leather.

fishing bag design, comparison of advantages and disadvantages of Chinese and American design levels

Chinese Design Level:

Advantages:

• Low cost materials and labor

• High quality craftsmanship

• Variety of styles and colors

• Durable and long-lasting

Disadvantages:

• Limited customization options

• Limited design options

• Limited access to new technologies

American Design Level:

Advantages:

• High quality materials and craftsmanship

• Variety of styles and colors

• Access to new technologies

• Customizable designs

• High level of customer service

Disadvantages:

• Higher cost of materials and labor

• Limited access to certain materials and technologies

Top ten international fishing bag brands

1. Shimano

2. Rapala

3. Plano

4. Flambeau

5. Wild River

6. KastKing

7. Berkley

8. Frabill

9. Piscifun

10. Ugly Stik

About the brand of the fishing bag manufacturers

The fishing bag manufacturers are a company called Fishpond. They are based in Colorado and specialize in creating high-quality fishing bags and accessories. They have been in business since 2002 and have become a leader in the fishing industry. They offer a wide range of products, from tackle bags to fly fishing vests, and are known for their innovative designs and quality materials.

fishing bag manufacturer' skill requirements for production operators

Production operators in a fishing bag manufacturer must have a variety of skills in order to be successful. These skills include:

• Knowledge of the manufacturing process and the ability to read and interpret blueprints and technical drawings.

• Ability to use hand tools, power tools, and other equipment to assemble and fabricate components.

• Knowledge of safety procedures and the ability to follow them.

• Ability to work with a variety of materials, including fabrics, plastics, and metals.

• Ability to work with a team and follow instructions.

• Attention to detail and the ability to identify and correct errors.

• Good communication skills and the ability to work with minimal supervision.

• Physical strength and stamina to lift and move heavy materials.

Classification of fishing bag design styles

1. Traditional: This style of fishing bag is characterized by a classic, timeless look. It typically features a canvas or leather exterior, with a drawstring closure and multiple pockets for storage.

2. Modern: This style of fishing bag is characterized by a sleek, contemporary look. It typically features a lightweight, waterproof material, with a zipper closure and multiple pockets for storage.

3. Tactical: This style of fishing bag is characterized by a rugged, military-inspired look. It typically features a heavy-duty material, with a buckle closure and multiple pockets for storage.

4. Luxury: This style of fishing bag is characterized by a luxurious, high-end look. It typically features a premium material, with a zipper closure and multiple pockets for storage.

5. Eco-Friendly: This style of fishing bag is characterized by an environmentally-friendly look. It typically features a recycled material, with a drawstring closure and multiple pockets for storage.

Analysis of the competition trend of China's fishing bag market

The fishing bag market in China has seen a steady growth in recent years. This is due to the increasing popularity of fishing as a recreational activity, as well as the rising demand for quality fishing bags. As a result, the competition in the fishing bag market in China has become increasingly fierce.

In terms of competition, the fishing bag market in China is dominated by a few large companies. These companies have established a strong presence in the market and have been able to maintain their market share by offering quality products at competitive prices. In addition, these companies have also invested heavily in research and development to stay ahead of the competition.

In terms of pricing, the fishing bag market in China is highly competitive. Companies are constantly trying to undercut each other in order to gain market share. This has led to a decrease in prices, which has been beneficial for consumers.

In terms of product innovation, the fishing bag market in China is also highly competitive. Companies are constantly introducing new products and features in order to stay ahead of the competition. This has led to an increase in the variety of fishing bags available in the market.

Overall, the competition in the fishing bag market in China is intense. Companies are constantly trying to outdo each other in terms of pricing, product innovation, and marketing. This has led to a highly competitive market, which is beneficial for consumers.