water bladder

What is a water bladder?

A water bladder is a type of hydration system that is used to store and transport water. It is typically made of a flexible material such as rubber or plastic and is designed to fit inside a backpack or other container. The bladder is filled with water and then sealed, allowing the user to easily access the water while on the go.

The main application field of the water bladder

Water bladders are most commonly used for storing and transporting water. They are often used in emergency situations, such as natural disasters, when access to clean drinking water is limited. They are also used for recreational activities, such as camping and boating, and for industrial purposes, such as firefighting and dust suppression.

History of water bladder development

The history of water bladder development dates back to the early 1800s. In 1804, the first water bladder was developed by a French engineer named Jean-Jacques Perrier. He designed a bladder made of rubber and canvas that could be filled with water and used to store it. This bladder was used to provide water to troops during the Napoleonic Wars.

In the late 1800s, the first modern water bladder was developed by a German engineer named Carl von Linde. His design was made of rubber and canvas and could hold up to 10 liters of water. This bladder was used to provide water to troops during World War I.

In the early 1900s, the first plastic water bladder was developed by a British engineer named Arthur D. Little. His design was made of polyethylene and could hold up to 20 liters of water. This bladder was used to provide water to troops during World War II.

Today, water bladders are used in a variety of applications, including camping, hiking, and military operations. They are made of a variety of materials, including rubber, canvas, and plastic, and can hold up to several hundred liters of water.

The development trend of the water bladder industry

The water bladder industry is expected to experience significant growth in the coming years due to increasing demand for water storage solutions. The industry is expected to benefit from the growing demand for water storage solutions in both residential and commercial applications. Additionally, the industry is expected to benefit from the increasing demand for water bladders in the military and emergency response sectors. The industry is also expected to benefit from the increasing demand for water bladders in the agricultural sector, as farmers look for ways to store and transport water for irrigation and other purposes. Furthermore, technological advancements in the industry are expected to drive growth, as new materials and designs are developed to improve the performance and durability of water bladders.

Why do we need water bladder?

Water bladders are an essential piece of equipment for anyone who needs to transport and store water. They are lightweight, collapsible, and easy to transport, making them ideal for camping, hiking, and other outdoor activities. They are also great for emergency preparedness, as they can be filled with clean water and stored for long periods of time.

When did humans start using water bladder?

Humans have been using water bladders for centuries, with evidence of their use dating back to ancient Egypt. The earliest known water bladders were made from animal skins and were used to store and transport water.

Inventor of the water bladder

The water bladder was invented by the French engineer and inventor, Jean-Jacques Perrier, in 1791. He was the first to develop a device that could store and transport water in a flexible container. The device was made of a rubberized fabric and was filled with water through a valve. The water bladder was used to supply water to troops in the field and was also used to store water on ships.

What material is suitable for water bladder

Water bladders are typically made from a variety of materials, including polyurethane, PVC, and nylon. Polyurethane is the most common material used for water bladders, as it is lightweight, durable, and resistant to punctures and tears. PVC and nylon are also popular materials, as they are both lightweight and durable.

How can water bladder manufacturers improve production quality?

1. Invest in high-quality materials: Investing in high-quality materials is essential for producing quality water bladders. Look for materials that are durable, lightweight, and resistant to punctures and tears.

2. Implement quality control measures: Establishing quality control measures is essential for ensuring that all water bladders meet the highest standards of quality. This includes inspecting each bladder for defects, testing for leaks, and ensuring that all seams are properly sealed.

3. Utilize advanced manufacturing techniques: Utilizing advanced manufacturing techniques such as injection molding and thermoforming can help to improve the quality of water bladders. These techniques can help to create a more consistent product with fewer defects.

4. Invest in training: Investing in training for employees can help to ensure that they are knowledgeable about the production process and can identify any potential issues. This can help to reduce the number of defective products and improve overall production quality.

How to choose the water bladder manufacturer with the best quality?

1. Research the manufacturer’s reputation: Check online reviews and customer feedback to get an idea of the manufacturer’s quality and customer service.

2. Ask for samples: Ask the manufacturer to provide samples of their water bladders so you can inspect the quality and craftsmanship.

3. Check certifications: Make sure the manufacturer is certified by a reputable organization such as the American Society for Testing and Materials (ASTM).

4. Ask about materials: Ask the manufacturer what materials they use to make their water bladders and make sure they are using high-quality materials.

5. Ask about warranties: Make sure the manufacturer offers a warranty on their water bladders. This will give you peace of mind that the product is of good quality.

What is the water bladder manufacturer?

There are many different water bladder manufacturers, including Hydrapak, Platypus, Source, Geigerrig, and CamelBak.

What are the classifications of water bladder?

1. Hydration Bladders: These are the most common type of water bladder and are designed to be used with a hydration pack. They are typically made of a flexible material such as neoprene or nylon and feature a bite valve for easy drinking.

2. Collapsible Water Bladders: These are lightweight and foldable water bladders that are designed to be easily stored and transported. They are typically made of a lightweight material such as silicone or polyurethane and feature a wide opening for easy filling.

3. Hard-Shell Water Bladders: These are rigid water bladders that are designed to be used in more extreme conditions. They are typically made of a hard plastic material and feature a wide opening for easy filling.

4. Water Reservoirs: These are large water bladders that are designed to be used in industrial or agricultural applications. They are typically made of a heavy-duty material such as PVC or polyethylene and feature a wide opening for easy filling.

What products can water bladder manufacturers produce?

Water bladder manufacturers can produce a wide range of products, including water storage tanks, water storage bladders, water filtration systems, water pumps, water purification systems, water treatment systems, water softeners, water heaters, and water coolers. They can also produce custom-made water bladders for specific applications.

Which companies are more worthy of cooperation in purchasing water bladder in China?

1. Guangzhou Yiqile Water Bladder Co., Ltd.

2. Shanghai Yiqile Water Bladder Co., Ltd.

3. Hangzhou Yiqile Water Bladder Co., Ltd.

4. Shenzhen Yiqile Water Bladder Co., Ltd.

5. Beijing Yiqile Water Bladder Co., Ltd.

6. Ningbo Yiqile Water Bladder Co., Ltd.

7. Wuxi Yiqile Water Bladder Co., Ltd.

8. Xiamen Yiqile Water Bladder Co., Ltd.

9. Qingdao Yiqile Water Bladder Co., Ltd.

10. Tianjin Yiqile Water Bladder Co., Ltd.

What are the specific requirements of water bladder manufacturer?

1. The manufacturer must have experience in producing water bladders and other related products.

2. The manufacturer must have the necessary equipment and machinery to produce water bladders.

3. The manufacturer must have a quality control system in place to ensure the quality of the water bladders.

4. The manufacturer must have a reliable supply chain to ensure timely delivery of the water bladders.

5. The manufacturer must have a good customer service system to address customer queries and complaints.

6. The manufacturer must have a good understanding of the regulations and standards related to water bladders.

7. The manufacturer must have a good understanding of the market and the needs of the customers.

8. The manufacturer must have a good understanding of the environmental impact of the production process.

9. The manufacturer must have a good understanding of the safety requirements related to water bladders.

10. The manufacturer must have a good understanding of the materials used in the production of water bladders.

What production equipment do water bladder manufacturer need?

1. Sewing machines

2. Cutting machines

3. Heat sealing machines

4. Ultrasonic welding machines

5. Printing machines

6. Testing equipment

7. Material handling equipment

8. Packaging equipment

Analysis on the layout of water bladder manufacturer in China's industrial chain

China's water bladder manufacturing industry is a highly fragmented industry, with a large number of small and medium-sized enterprises scattered throughout the country. The industry is characterized by a complex and diverse industrial chain, with a wide range of products and services.

At the top of the industrial chain is the raw material suppliers, who provide the raw materials for the production of water bladders. These raw materials include polyethylene, polypropylene, nylon, and other synthetic materials. The raw materials are then processed by the manufacturers into the finished product.

The next step in the industrial chain is the production of the water bladders. This involves the use of specialized machinery and equipment to produce the bladders in various sizes and shapes. The production process also includes the use of various chemicals and additives to ensure the quality of the product.

The final step in the industrial chain is the distribution of the water bladders. This involves the transportation of the bladders to the end-users, such as water parks, swimming pools, and other recreational facilities. The distribution process also includes the packaging and labeling of the bladders.

Overall, the layout of the water bladder manufacturing industry in China is complex and diverse. The industry is highly fragmented, with a large number of small and medium-sized enterprises scattered throughout the country. The industry is characterized by a wide range of products and services, and the production process involves the use of specialized machinery and equipment. The distribution process also includes the packaging and labeling of the bladders.

Production scale and production capacity of water bladder manufacturer

The production scale and production capacity of a water bladder manufacturer will depend on the size of the company and the type of bladders they produce. Generally, larger companies will have larger production scales and capacities, while smaller companies may have smaller production scales and capacities. The production capacity of a water bladder manufacturer will also depend on the type of bladders they produce, as well as the materials used to make them. For example, a manufacturer that produces large, heavy-duty bladders may have a higher production capacity than a manufacturer that produces smaller, lighter-duty bladders.

water bladder manufacturer produce equipment, how to improve equipment management efficiency

1. Establish a comprehensive equipment management system: Establish a comprehensive equipment management system to ensure that all equipment is properly tracked and managed.

2. Implement preventive maintenance: Implement preventive maintenance to ensure that all equipment is regularly inspected and maintained to prevent breakdowns and reduce downtime.

3. Utilize technology: Utilize technology such as barcode scanners, RFID tags, and other tracking systems to streamline the equipment management process.

4. Train personnel: Train personnel on proper equipment management procedures to ensure that all equipment is properly handled and maintained.

5. Monitor usage: Monitor usage of equipment to ensure that it is being used efficiently and not being overused or abused.

6. Establish a feedback system: Establish a feedback system to allow personnel to provide feedback on the performance of the equipment and any issues they may have encountered.

7. Utilize data: Utilize data to analyze the performance of the equipment and identify areas for improvement.

What is the maintenance content of the water bladder manufacturer's production equipment?

1. Regularly check the lubrication of the equipment and add lubricating oil in time.

2. Regularly check the wear of the parts and replace them in time.

3. Regularly check the tightness of the screws and fasteners, and tighten them in time.

4. Regularly check the electrical components and replace them in time.

5. Regularly clean the equipment and keep it clean.

6. Regularly check the water supply system and replace the water in time.

7. Regularly check the air pressure system and adjust the pressure in time.

8. Regularly check the temperature of the equipment and adjust it in time.

Advantages and development direction of water bladder manufacturers

1. Advantages:

(1) Water bladder manufacturers have strong production capacity and can produce a variety of water bladders with different sizes and shapes.

(2) The water bladder manufacturers have advanced production technology and equipment, which can ensure the quality of the products.

(3) The water bladder manufacturers have a professional team of technicians and designers, which can provide customers with professional technical support and design services.

(4) The water bladder manufacturers have a complete quality control system, which can ensure the quality of the products.

2. Development direction:

(1) Develop new products with better performance and more functions.

(2) Improve the production technology and equipment to ensure the quality of the products.

(3) Strengthen the research and development of new materials to meet the needs of different customers.

(4) Strengthen the cooperation with customers to provide better services.

Matters needing attention in the development of raw material supply chain for water bladder manufacturer

1. Establish a reliable supply chain: It is important to establish a reliable supply chain for raw materials. This includes finding reliable suppliers, negotiating contracts, and ensuring that the raw materials are of high quality and delivered on time.

2. Monitor supplier performance: It is important to monitor the performance of suppliers to ensure that they are meeting the quality and delivery requirements. This includes conducting regular audits and reviews of supplier performance.

3. Develop a risk management plan: It is important to develop a risk management plan to identify potential risks and develop strategies to mitigate them. This includes identifying potential supply chain disruptions, developing contingency plans, and monitoring supplier performance.

4. Establish a quality control system: It is important to establish a quality control system to ensure that the raw materials meet the required standards. This includes conducting regular inspections and tests of the raw materials.

5. Develop a pricing strategy: It is important to develop a pricing strategy to ensure that the raw materials are priced competitively. This includes researching the market and negotiating with suppliers to get the best prices.

water bladder manufacturer production technology coverage

Water bladder manufacturers typically use a variety of production technologies to create their products. These technologies include rotational molding, thermoforming, and welding. Rotational molding is a process in which a heated mold is filled with a powdered plastic material and then rotated in two directions to evenly distribute the material. The mold is then cooled and the finished product is removed. Thermoforming is a process in which a sheet of plastic is heated and then formed into a desired shape. Welding is a process in which two pieces of plastic are joined together using heat and pressure.

Instructions for cooperation with water bladder manufacturer

1. Establish a clear timeline for the project. Make sure to include deadlines for both parties to ensure that the project is completed on time.

2. Determine the scope of the project. This includes the type of water bladder, the size, the materials, and any other specifications.

3. Agree on a payment plan. This should include the cost of the materials, the cost of labor, and any other associated costs.

4. Discuss the quality control process. Make sure that the manufacturer is aware of any standards that need to be met and that they have a plan in place to ensure that the product meets those standards.

5. Establish a communication plan. This should include how often the two parties will communicate, what methods of communication will be used, and who will be responsible for initiating contact.

6. Discuss the warranty and return policy. Make sure that both parties are aware of the terms of the warranty and return policy and that they are in agreement.

7. Sign a contract. This should include all of the details of the project, including the timeline, scope, payment plan, quality control process, communication plan, and warranty and return policy.

water bladder manufacturer production line

The production line for a water bladder manufacturer typically includes the following steps:

1. Cutting: The fabric used to make the bladders is cut to the desired size and shape.

2. Sewing: The edges of the fabric are sewn together to form the bladder.

3. Testing: The bladder is tested for leaks and other defects.

4. Filling: The bladder is filled with water and sealed.

5. Packaging: The bladder is packaged for shipping.

Production profit of water bladder manufacturer

The profit of a water bladder manufacturer depends on a variety of factors, including the cost of materials, labor, overhead, and marketing. The manufacturer's profit is calculated by subtracting all of these costs from the total revenue generated from sales. The profit margin of a water bladder manufacturer can vary greatly depending on the size of the company, the quality of the product, and the market demand.

Analysis of R&D capabilities of global water bladder manufacturer

A global water bladder manufacturer must have strong research and development (R&D) capabilities in order to remain competitive in the market. R&D capabilities are essential for a company to develop new products, improve existing products, and stay ahead of the competition. In order to analyze the R&D capabilities of a global water bladder manufacturer, it is important to consider the following factors:

1. Research and Development Budget: A company’s R&D budget is a key indicator of its commitment to innovation and product development. A company with a larger R&D budget is likely to have more resources available for research and development activities.

2. Research and Development Team: A company’s R&D team should be composed of experienced professionals with expertise in the field of water bladder manufacturing. The team should have the necessary skills and knowledge to develop new products and improve existing ones.

3. Technology: A company should have access to the latest technologies and equipment in order to develop new products and improve existing ones. This includes access to advanced materials, manufacturing processes, and testing equipment.

4. Partnerships: A company should have strong partnerships with other companies and research institutions in order to access new technologies and resources. This can help a company stay ahead of the competition and develop new products faster.

5. Intellectual Property: A company should have a strong intellectual property portfolio in order to protect its innovations and products from competitors. This includes patents, trademarks, and copyrights.

By analyzing these factors, it is possible to get a better understanding of the R&D capabilities of a global water bladder manufacturer. A company with strong R&D capabilities is likely to be more successful in the market and have a competitive edge over its competitors.

Covered content of the water bladder manufacturer's production process

1. Design: The water bladder manufacturer will design the product according to the customer's specifications. This includes the size, shape, and material of the bladder.

2. Cutting: The manufacturer will then cut the material to the desired size and shape.

3. Sewing: The manufacturer will then sew the material together to form the bladder.

4. Testing: The manufacturer will then test the bladder for leaks and other defects.

5. Packaging: The manufacturer will then package the bladder for shipping.

Detailed explanation of the production process of water bladder manufacturer

1. Design: The first step in the production process of a water bladder manufacturer is to design the product. This includes creating a prototype, selecting the right materials, and determining the size and shape of the bladder.

2. Cutting: Once the design is finalized, the manufacturer will cut the material to the desired size and shape. This is usually done with a die-cutting machine.

3. Sewing: The next step is to sew the pieces together. This is done with a specialized sewing machine that is designed to handle the material.

4. Testing: After the bladder is sewn together, it is tested for leaks and other defects. This is done by filling the bladder with water and checking for any leaks.

5. Finishing: The last step in the production process is to finish the bladder. This includes adding any necessary features such as straps, handles, or valves. The bladder is then inspected one final time before it is ready to be shipped.

Production process management of water bladder manufacturers

1. Design: Water bladder manufacturers must first design the product according to customer requirements. This includes selecting the right material, size, shape, and other features.

2. Procurement: Once the design is finalized, the manufacturer must source the necessary raw materials and components. This includes selecting the right suppliers and negotiating the best prices.

3. Production: The next step is to produce the water bladder. This includes cutting, welding, and assembling the components.

4. Quality Control: Quality control is an important step in the production process. The manufacturer must inspect the product for any defects or inconsistencies.

5. Packaging: Once the product is approved, it must be packaged for shipping. This includes selecting the right packaging materials and labeling the product.

6. Shipping: The final step is to ship the product to the customer. This includes selecting the right carrier and ensuring the product arrives safely.

water bladder manufacturer need to meet the following environmental protection requirements

1. Use materials that are safe for the environment and do not contain any hazardous substances.

2. Ensure that all manufacturing processes are conducted in a manner that minimizes environmental impact.

3. Adhere to all applicable environmental regulations and standards.

4. Implement waste management and recycling programs to reduce the amount of waste generated.

5. Utilize energy-efficient technologies and processes to reduce energy consumption.

6. Utilize renewable energy sources, such as solar or wind power, to reduce reliance on fossil fuels.

7. Develop and implement a plan to reduce water consumption.

8. Develop and implement a plan to reduce air pollution.

9. Develop and implement a plan to reduce the use of hazardous chemicals.

10. Develop and implement a plan to reduce the use of non-renewable resources.

How can water bladder manufacturer improve production efficiency

1. Invest in Automation: Investing in automation can help water bladder manufacturers increase production efficiency by reducing manual labor and increasing accuracy. Automation can also help reduce costs associated with labor and materials.

2. Streamline Processes: Streamlining processes can help water bladder manufacturers reduce waste and increase efficiency. This can include streamlining production processes, inventory management, and quality control.

3. Invest in Quality Control: Investing in quality control can help water bladder manufacturers ensure that their products meet customer expectations and industry standards. Quality control can also help reduce costs associated with rework and scrap.

4. Invest in Training: Investing in training can help water bladder manufacturers ensure that their employees are knowledgeable and skilled in the production process. This can help reduce errors and increase efficiency.

5. Utilize Lean Manufacturing: Utilizing lean manufacturing principles can help water bladder manufacturers reduce waste and increase efficiency. This can include reducing inventory, streamlining processes, and utilizing just-in-time production.

How do water bladder manufacturer implement new product development

1. Research and Development: Water bladder manufacturers should conduct research and development to identify customer needs and develop new products that meet those needs. This includes researching the market, understanding customer preferences, and developing innovative solutions.

2. Design and Prototyping: Once the research and development phase is complete, the manufacturer should design and prototype the new product. This includes creating a 3D model, testing the product, and making any necessary changes.

3. Testing and Validation: The manufacturer should then test and validate the new product to ensure it meets customer needs and safety standards. This includes conducting laboratory tests, field tests, and customer feedback surveys.

4. Production and Distribution: Once the product is ready for production, the manufacturer should create a production plan and begin manufacturing the product. The manufacturer should also create a distribution plan to ensure the product is available to customers.

How to improve the manufacturing process of water bladder manufacturer

1. Invest in Automation: Investing in automation can help streamline the manufacturing process and reduce labor costs. Automation can also help reduce errors and improve quality control.

2. Implement Lean Manufacturing: Lean manufacturing is a process that focuses on eliminating waste and improving efficiency. Implementing lean manufacturing techniques can help reduce costs and improve the overall quality of the product.

3. Invest in Quality Control: Quality control is essential for any manufacturing process. Investing in quality control measures can help ensure that the product meets customer expectations.

4. Invest in Training: Training employees on the latest manufacturing techniques can help improve the efficiency of the process.

5. Invest in Technology: Investing in the latest technology can help improve the speed and accuracy of the manufacturing process.

6. Improve Communication: Improving communication between departments can help ensure that everyone is on the same page and working towards the same goal.

7. Monitor the Process: Monitoring the manufacturing process can help identify areas of improvement and ensure that the process is running smoothly.

How do water bladder manufacturer solve the application of new technologies

Water bladder manufacturers can use new technologies to improve the quality of their products. For example, they can use advanced materials such as polyurethane and PVC to create more durable and lightweight water bladders. They can also use new technologies such as RF welding and heat sealing to create stronger and more reliable seals. Additionally, they can use 3D printing to create custom-shaped water bladders for specific applications. Finally, they can use computer-aided design (CAD) software to create more efficient and cost-effective designs.

How do water bladder manufacturer establish a sound supply chain management

1. Establish a clear supply chain strategy: A water bladder manufacturer should develop a clear supply chain strategy that outlines the company’s goals and objectives, as well as the strategies and tactics that will be used to achieve them.

2. Develop strong supplier relationships: A water bladder manufacturer should develop strong relationships with its suppliers to ensure that they are able to provide the necessary materials and services in a timely manner.

3. Utilize technology: A water bladder manufacturer should utilize technology to streamline the supply chain process and ensure that all stakeholders are able to access the necessary information in a timely manner.

4. Monitor performance: A water bladder manufacturer should monitor the performance of its suppliers and other stakeholders to ensure that they are meeting the company’s expectations.

5. Implement quality control measures: A water bladder manufacturer should implement quality control measures to ensure that the products they produce meet the highest standards of quality.

water bladder manufacturer service and quality system

A water bladder manufacturer should have a quality system in place to ensure that their products meet the highest standards of safety and performance. This system should include a comprehensive set of procedures and processes to ensure that all products are manufactured to the highest quality standards. The system should include a quality assurance program, a quality control program, and a quality management system. The quality assurance program should include a system of checks and balances to ensure that all products meet the required specifications. The quality control program should include a system of inspections and tests to ensure that all products meet the required standards. The quality management system should include a system of documentation and records to ensure that all products are manufactured to the highest quality standards.

What are the services of water bladder manufacturer?

Water bladder manufacturers typically provide a range of services, including custom design and fabrication of water bladders, installation and maintenance of water bladders, and repair and replacement of water bladders. They may also provide consulting services to help customers select the best water bladder for their needs. Additionally, some water bladder manufacturers may offer additional services such as water testing and filtration, water storage tank installation, and water delivery services.

How do water bladder manufacturer establish their own water bladder dealer channels

1. Develop a comprehensive marketing strategy: A comprehensive marketing strategy should be developed to identify target markets, develop a pricing strategy, and create a promotional plan.

2. Develop a dealer network: A dealer network should be established to reach potential customers. This can be done through direct sales, online sales, or through a network of distributors.

3. Develop a customer service strategy: A customer service strategy should be developed to ensure that customers are satisfied with their purchases. This includes providing technical support, responding to customer inquiries, and providing warranty services.

4. Develop a product line: A product line should be developed to meet the needs of different customers. This includes offering a variety of sizes, colors, and features.

5. Develop a distribution strategy: A distribution strategy should be developed to ensure that the water bladder manufacturer’s products are available in the right places. This includes working with retailers, wholesalers, and distributors.

Customer group and service level of water bladder manufacturer

The customer group for a water bladder manufacturer would likely include outdoor enthusiasts, athletes, and military personnel. The service level of the manufacturer would depend on the specific product and services offered. Generally, the service level would include product customization, quality assurance, and customer service.

R&D direction of water bladder manufacturer industry

1. Developing new materials: Developing new materials for water bladder manufacturing that are more durable, lightweight, and cost-effective.

2. Automation: Developing automated production processes to reduce labor costs and improve efficiency.

3. Design: Developing innovative designs for water bladders that are more ergonomic and aesthetically pleasing.

4. Quality control: Developing quality control systems to ensure that water bladders meet safety and performance standards.

5. Recycling: Developing methods for recycling used water bladders to reduce waste and environmental impact.

How to improve the quality of water bladder manufacturers

1. Invest in high-quality materials: Investing in high-quality materials is essential for producing quality water bladders. Look for materials that are durable, lightweight, and resistant to punctures and tears.

2. Utilize advanced manufacturing techniques: Utilizing advanced manufacturing techniques such as injection molding and rotational molding can help to ensure that the water bladders are of the highest quality.

3. Implement quality control measures: Quality control measures should be implemented throughout the manufacturing process to ensure that the water bladders meet the highest standards of quality.

4. Provide customer service: Providing excellent customer service is essential for ensuring customer satisfaction. Make sure that customers can easily contact the manufacturer with any questions or concerns they may have.

5. Offer warranties: Offering warranties on the water bladders can help to ensure that customers are satisfied with their purchase.

After-sales compensation terms for water bladder manufacturer

1. Warranty: The water bladder manufacturer should provide a warranty for all products sold. The warranty should cover any defects in materials or workmanship for a period of at least one year from the date of purchase.

2. Replacement: The water bladder manufacturer should provide a replacement for any product that fails to meet the manufacturer’s specifications within the warranty period.

3. Refund: The water bladder manufacturer should provide a full refund for any product that fails to meet the manufacturer’s specifications within the warranty period.

4. Repair: The water bladder manufacturer should provide repair services for any product that fails to meet the manufacturer’s specifications within the warranty period.

5. Shipping: The water bladder manufacturer should provide free shipping for any product that needs to be returned for repair or replacement.

6. Customer Service: The water bladder manufacturer should provide prompt and courteous customer service to address any questions or concerns about the product.

water bladder manufacturer are more worthy of cooperation if they have patents

Yes, water bladder manufacturers with patents are more worthy of cooperation because they have invested in research and development to create a unique product. Patents provide legal protection for the manufacturer's intellectual property, which can help them to protect their market share and increase their profits. Additionally, patents can also help to differentiate the manufacturer's product from competitors, which can help to attract more customers.

Product quality control of water bladder manufacturer

1. Establish a quality control system: Establish a quality control system that includes a set of procedures and processes to ensure that the water bladder manufacturer is producing products that meet the required standards.

2. Inspect raw materials: Inspect all raw materials used in the production of water bladders to ensure they meet the required standards.

3. Test the product: Test the water bladders for any defects or inconsistencies in quality.

4. Monitor production process: Monitor the production process to ensure that the water bladders are being produced according to the required standards.

5. Document results: Document the results of all quality control tests and inspections.

6. Take corrective action: Take corrective action if any defects or inconsistencies are found in the water bladders.

7. Train employees: Train employees on the quality control system and procedures.

8. Regularly review quality control system: Regularly review the quality control system to ensure it is up to date and effective.

The international production mode adopted by water bladder manufacturers

Water bladder manufacturers typically use an international production mode that involves outsourcing production to countries with lower labor costs. This allows them to reduce their production costs and increase their profits. The production process typically involves the manufacture of the bladders in the country of origin, followed by the assembly of the bladders in the destination country. This allows the manufacturer to take advantage of the lower labor costs in the country of origin while still maintaining quality control in the destination country.

What services are included in the water bladder manufacturer's after-sales service?

The after-sales service of a water bladder manufacturer typically includes product installation, maintenance, repair, and replacement services. They may also offer technical support and customer service to help customers with any questions or concerns they may have. Additionally, some manufacturers may offer warranties on their products to ensure customer satisfaction.

What is water bladder design?

Water bladder design is a type of water storage system that uses a flexible, airtight bladder to store water. The bladder is typically made of a durable material such as rubber or plastic and is designed to hold a specific amount of water. The bladder is then placed inside a larger container, such as a tank or cistern, and connected to a water supply. This allows for easy access to the stored water and helps to keep it clean and safe for use.

water bladder manufacturer' skill requirements for production operators

Production operators in a water bladder manufacturer must have a variety of skills and abilities.

• Knowledge of the production process and the ability to follow instructions accurately.

• Ability to use hand tools and machinery safely and efficiently.

• Ability to read and interpret technical drawings and diagrams.

• Ability to identify and troubleshoot problems with machinery and equipment.

• Ability to work with a team and communicate effectively with other team members.

• Ability to work in a fast-paced environment and meet deadlines.

• Ability to lift and move heavy objects.

• Knowledge of safety protocols and procedures.

• Knowledge of quality control processes and procedures.

water bladder design, comparison of advantages and disadvantages of Chinese and American design levels

Chinese Design Level:

Advantages:

• Low cost materials and production costs

• Lightweight and easy to transport

• Durable and long-lasting

• Variety of sizes and shapes available

Disadvantages:

• Poor quality control

• Poor insulation

• Poor sealing

• Poor customer service

American Design Level:

Advantages:

• High quality materials and production standards

• Excellent insulation

• Superior sealing

• Excellent customer service

• Variety of sizes and shapes available

Disadvantages:

• Higher cost materials and production costs

• Heavier and more difficult to transport

water bladder design, what are the shortcomings of Chinese enterprises?

1. Lack of innovation: Chinese enterprises often lack the ability to innovate and develop new products.

2. Poor quality control: Chinese enterprises often lack the necessary quality control measures to ensure the safety and reliability of their products.

3. Limited resources: Chinese enterprises often lack the resources to invest in research and development, which can limit their ability to develop new products.

4. Limited access to international markets: Chinese enterprises often lack the necessary resources and connections to access international markets.

5. Poor customer service: Chinese enterprises often lack the necessary customer service infrastructure to provide adequate support to their customers.

Classification of water bladder design styles

1. Collapsible: These water bladders are designed to be folded or rolled up when not in use, making them easy to store and transport.

2. Rigid: These water bladders are designed to be rigid and are usually made of hard plastic or metal. They are more durable than collapsible bladders, but are not as easy to store or transport.

3. Hydration Pack: These water bladders are designed to be worn on the back and are usually made of lightweight materials. They are designed to be comfortable and provide easy access to water while on the go.

4. Insulated: These water bladders are designed to keep water cold for extended periods of time. They are usually made of insulated materials and are great for outdoor activities.

5. Gravity-Fed: These water bladders are designed to be hung from a tree or other elevated structure and use gravity to dispense water. They are great for camping and other outdoor activities.

About the brand of the water bladder manufacturers

The brand of the water bladder manufacturers is Hydrapak. Hydrapak is a leading manufacturer of hydration solutions for outdoor and active lifestyles. They specialize in creating innovative, high-performance hydration systems for athletes, adventurers, and outdoor enthusiasts. Their products are designed to keep you hydrated and comfortable in any environment. Hydrapak is committed to providing the highest quality products and customer service.

Top ten international water bladder brands

1. Platypus

2. CamelBak

3. Geigerrig

4. Hydrapak

5. Source Outdoor

6. Osprey

7. MSR

8. Nalgene

9. Vapur

10. Hydration Depot

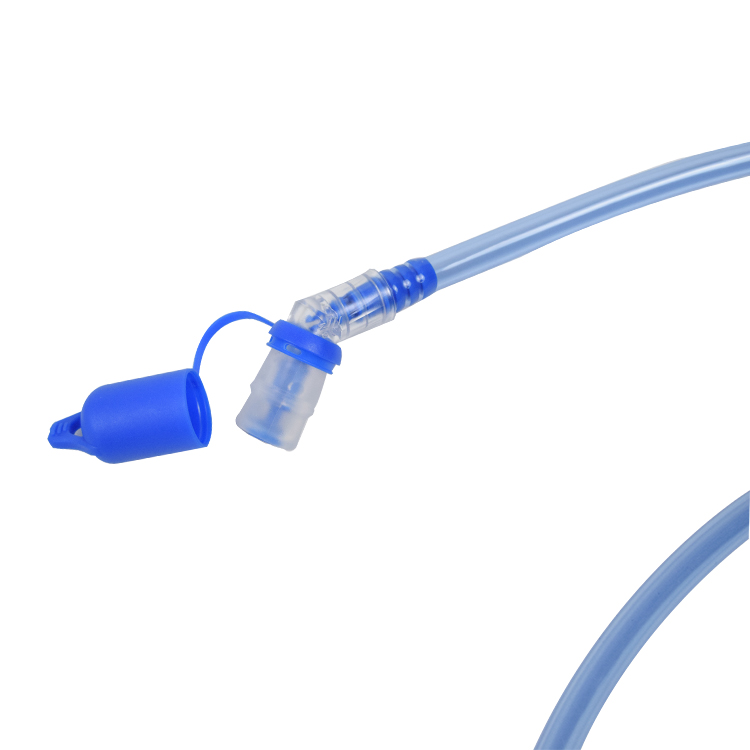

Effect drawing of water bladder design

A water bladder design is a type of container that is used to store and transport water. It is typically made of a flexible material such as rubber or plastic and is designed to be filled with water and then sealed. The design typically consists of a large, flexible bag with a valve at the top for filling and a spout at the bottom for draining. The bag is usually designed to be collapsible, allowing it to be easily stored when not in use. The drawing of a water bladder design would include a large, flexible bag with a valve at the top and a spout at the bottom. The bag would be drawn in a collapsed state, with the valve and spout visible. The drawing would also include a line indicating the maximum fill level of the bag.

Skill requirements for designers

1. Knowledge of design principles and techniques: Designers should have a strong understanding of design principles such as composition, color theory, typography, and layout. They should also be familiar with various design techniques such as wireframing, prototyping, and user experience design.

2. Knowledge of software: Designers should be proficient in the use of design software such as Adobe Photoshop, Illustrator, InDesign, and Sketch. They should also be familiar with other software such as HTML, CSS, and JavaScript.

3. Creative thinking: Designers should be able to think creatively and come up with innovative solutions to design problems. They should also be able to think outside the box and come up with unique ideas.

4. Communication skills: Designers should be able to communicate effectively with clients, colleagues, and other stakeholders. They should be able to explain their design decisions and present their work in a clear and concise manner.

5. Time management: Designers should be able to manage their time effectively and meet deadlines. They should also be able to prioritize tasks and manage multiple projects at once.

Analysis of the competition trend of China's water bladder market

The water bladder market in China has seen a steady growth in recent years. This is due to the increasing demand for water bladders from consumers, as well as the growing popularity of outdoor activities such as camping and hiking.

The competition in the Chinese water bladder market is becoming increasingly fierce. This is due to the entry of new players into the market, as well as the increasing number of existing players. The competition is also driven by the increasing number of innovative products being introduced into the market.

In terms of pricing, the competition in the Chinese water bladder market is becoming increasingly intense. This is due to the fact that the cost of production is increasing, as well as the fact that the market is becoming increasingly saturated. As a result, companies are forced to reduce their prices in order to remain competitive.

In terms of product quality, the competition in the Chinese water bladder market is also becoming increasingly intense. This is due to the fact that consumers are becoming increasingly aware of the importance of quality when it comes to water bladders. As a result, companies are forced to invest in research and development in order to produce high-quality products.

Overall, the competition in the Chinese water bladder market is becoming increasingly intense. This is due to the increasing demand for water bladders from consumers, as well as the increasing number of players in the market. Companies must invest in research and development in order to remain competitive and produce high-quality products.