water bladder

How many types of water bladder are there?

There are several types of water bladders, including hydration bladders, water storage bladders, and water transport bladders.

The main function of the water bladder

The main function of a water bladder is to store and transport water. It is typically made of a flexible material such as rubber or plastic and is designed to be filled with water and then sealed. The bladder can then be carried or strapped to a person's back, allowing them to easily transport water with them. Water bladders are commonly used for camping, hiking, and other outdoor activities.

How is the water bladder produced?

Water bladders are typically made from a variety of materials, including polyurethane, PVC, and rubber. The material is cut to size and then sealed together with heat or adhesives. The bladder is then tested for leaks and pressure before being filled with water. Finally, the bladder is fitted with a valve and ready for use.

How to purchase water bladder from China?

1. Research potential suppliers: Start by researching potential suppliers in China. You can use online resources such as Alibaba, Global Sources, and Made-in-China to find suppliers that offer water bladders.

2. Contact suppliers: Once you have identified potential suppliers, contact them to inquire about their products and services. Ask for samples, pricing, and delivery times.

3. Negotiate terms: Negotiate terms with the supplier, such as payment terms, delivery times, and any other conditions.

4. Place an order: Once you have agreed on terms, place an order with the supplier. Make sure to provide clear instructions and payment information.

5. Receive and inspect the product: Once the product has been delivered, inspect it to make sure it meets your expectations. If there are any issues, contact the supplier to resolve them.

When was the water bladder invented?

The water bladder was invented in the late 19th century.

What kinds of fabrics are there for making water bladder?

The most common fabrics used for making water bladders are nylon, polyurethane, and thermoplastic polyurethane (TPU). Nylon is lightweight and durable, making it a popular choice for water bladders. Polyurethane is also lightweight and durable, but it is more flexible and resistant to punctures. TPU is the most durable and flexible of the three fabrics, making it the best choice for water bladders that will be used in extreme conditions.

What is the original appearance of the water bladder?

The original appearance of a water bladder is typically a flexible, collapsible container made of a waterproof material such as rubber or plastic. It is designed to hold liquids and is often used to store water for camping, hiking, and other outdoor activities.

Which material water bladder is the most comfortable to wear?

The most comfortable water bladder to wear is one made of a lightweight, breathable material such as neoprene or mesh. These materials are designed to be lightweight and comfortable against the skin, while also providing adequate insulation to keep your water cool. Additionally, look for a water bladder with adjustable straps and a wide, comfortable waistband for added comfort.

How does the water bladder manufacturer produce the water bladder?

The water bladder manufacturer typically begins by cutting the fabric for the bladder from a roll of material. The fabric is then sewn together to form the bladder shape. The bladder is then sealed and tested for leaks. Once the bladder passes the leak test, it is ready to be filled with water. The bladder is then sealed again and tested for leaks once more. Finally, the bladder is ready to be shipped to the customer.

What products can water bladder manufacturers produce?

Water bladder manufacturers can produce a wide range of products, including water storage tanks, water storage bladders, water filtration systems, water pumps, water treatment systems, water purification systems, water softeners, water heaters, and water coolers. They can also produce custom-made water bladders for specific applications.

water bladder manufacturer need to have the following production equipment

1. Water Bladder Forming Machine

2. Water Bladder Cutting Machine

3. Water Bladder Sealing Machine

4. Water Bladder Welding Machine

5. Water Bladder Testing Machine

6. Water Bladder Printing Machine

7. Water Bladder Filling Machine

8. Water Bladder Packaging Machine

9. Water Bladder Inspection Machine

10. Water Bladder Storage Tank

Information reference for the distribution map of water bladder manufacturer in China's industrial chain

1. China Water Bladder Industry Report, 2018-2022:

This report provides an in-depth analysis of the water bladder industry in China, including market size, production, consumption, import and export, and competitive landscape. It also provides a detailed analysis of the industry chain, including upstream and downstream industries, raw materials, and technology.

2. China Water Bladder Industry Chain Report, 2018-2022:

This report provides an in-depth analysis of the water bladder industry chain in China, including upstream and downstream industries, raw materials, and technology. It also provides a detailed analysis of the industry chain, including market size, production, consumption, import and export, and competitive landscape.

3. China Water Bladder Industry Distribution Map, 2018-2022:

This report provides a detailed analysis of the distribution map of water bladder manufacturers in China, including their locations, production capacity, and market share. It also provides an overview of the industry chain, including upstream and downstream industries, raw materials, and technology.

Some suggestions for improving the utilization rate of equipment for water bladder manufacturer

1. Implement preventive maintenance: Regularly inspect and maintain equipment to ensure that it is in good working condition and reduce the risk of breakdowns.

2. Invest in automation: Automating certain processes can help reduce labor costs and increase efficiency.

3. Utilize predictive analytics: Utilizing predictive analytics can help identify potential problems before they occur and help prevent downtime.

4. Improve inventory management: Implementing an effective inventory management system can help reduce waste and ensure that the right parts are available when needed.

5. Invest in training: Investing in training for employees can help them become more efficient and knowledgeable about the equipment they are using.

6. Utilize data-driven decision making: Utilizing data-driven decision making can help identify areas of improvement and help optimize the utilization rate of equipment.

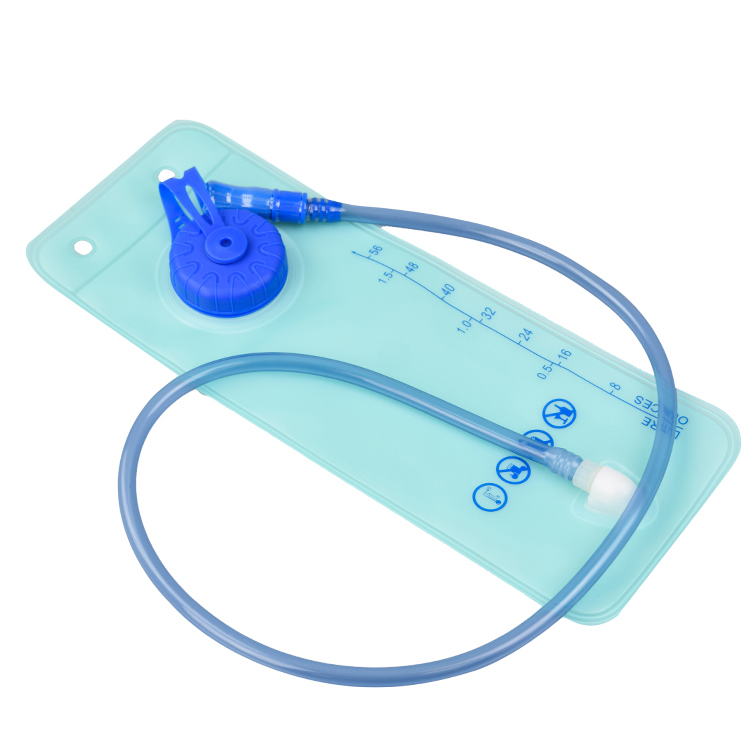

Design prototype of water bladder water bladder

The water bladder prototype would be a flexible, lightweight container made of a durable material such as nylon or polyester. It would have a wide opening at the top for easy filling and a smaller opening at the bottom for easy draining. The bladder would be designed with a valve at the top to control the flow of water and a pressure relief valve at the bottom to prevent over-pressurization. The bladder would also have straps or handles for easy carrying and a clip or loop for attaching to a backpack or other item. The bladder would be designed to be collapsible for easy storage when not in use.

What are the advantages of water bladder manufacturers with large-scale production compared with small-scale production?

1. Cost savings: Large-scale production allows for economies of scale, which can result in lower production costs.

2. Increased efficiency: Large-scale production allows for more efficient use of resources, resulting in higher output and faster production times.

3. Improved quality: Large-scale production allows for more consistent quality control, resulting in higher quality products.

4. Increased flexibility: Large-scale production allows for more flexibility in production, allowing for more customization and variety in products.

5. Increased market reach: Large-scale production allows for a wider reach in the market, allowing for more customers and potential sales.

Who are the global water bladder manufacturer with strong research and development capabilities? What are their advantages?

1. WATERTEC: Watertec is a global water bladder manufacturer with strong research and development capabilities. They specialize in the design and manufacture of custom water bladders for a variety of applications. Their advantages include a wide range of sizes and shapes, superior quality materials, and a commitment to customer service.

2. Aquatech: Aquatech is a global water bladder manufacturer with strong research and development capabilities. They specialize in the design and manufacture of custom water bladders for a variety of applications. Their advantages include a wide range of sizes and shapes, superior quality materials, and a commitment to customer service.

3. Waterflex: Waterflex is a global water bladder manufacturer with strong research and development capabilities. They specialize in the design and manufacture of custom water bladders for a variety of applications. Their advantages include a wide range of sizes and shapes, superior quality materials, and a commitment to customer service.

4. Water Tank Solutions: Water Tank Solutions is a global water bladder manufacturer with strong research and development capabilities. They specialize in the design and manufacture of custom water bladders for a variety of applications. Their advantages include a wide range of sizes and shapes, superior quality materials, and a commitment to customer service.

water bladder manufacturer raw material supply chain development and maintenance experience sharing

1. Establish a reliable raw material supply chain: Establishing a reliable raw material supply chain is essential for any water bladder manufacturer. It is important to identify reliable suppliers who can provide quality materials at competitive prices. It is also important to establish a good relationship with these suppliers to ensure that they are able to meet the needs of the manufacturer.

2. Monitor the quality of raw materials: Quality control is essential for any water bladder manufacturer. It is important to monitor the quality of raw materials to ensure that they meet the required standards. This can be done by conducting regular inspections and tests on the raw materials.

3. Develop a system for tracking raw materials: It is important to develop a system for tracking raw materials to ensure that they are being used efficiently and that they are not being wasted. This can be done by using software or other tracking systems.

4. Establish a system for managing inventory: It is important to establish a system for managing inventory to ensure that the right amount of raw materials are available when needed. This can be done by using software or other inventory management systems.

5. Develop a system for tracking production: It is important to develop a system for tracking production to ensure that the production process is running smoothly and efficiently. This can be done by using software or other tracking systems.

6. Develop a system for tracking customer orders: It is important to develop a system for tracking customer orders to ensure that orders are being fulfilled in a timely manner. This can be done by using software or other tracking systems.

Who invented the production process of water bladder manufacturers at first?

The first production process of water bladder manufacturers was invented by the German engineer Karl Heye in the late 19th century. Heye developed a process for producing rubberized fabric bladders that could be used for storing and transporting liquids. This process was later refined and improved upon by other manufacturers, leading to the modern production process used today.

Several update iterations experienced by water bladder manufacturer in production technology

1. Automation: Automating the production process with robotic arms and other automated machinery to reduce labor costs and increase efficiency.

2. Quality Control: Implementing quality control measures to ensure that all products meet the highest standards of quality.

3. Material Selection: Selecting the best materials for the production of water bladders, such as high-grade rubber and plastic.

4. Design Optimization: Optimizing the design of the water bladders to reduce weight and improve performance.

5. Cost Reduction: Utilizing cost-saving measures to reduce the cost of production and increase profits.

6. Process Improvement: Improving the production process to reduce waste and increase efficiency.

7. Technology Integration: Integrating new technologies into the production process to improve the quality and speed of production.

How many operators do water bladder manufacturer need for a production line?

The number of operators needed for a water bladder production line will depend on the size and complexity of the production line. Generally, a production line will require at least one operator to oversee the entire process, as well as additional operators to manage specific tasks such as cutting, welding, and assembly.

The comparison between the production profit of Chinese water bladder manufacturer and the previous 10 years

The production profit of Chinese water bladder manufacturers has increased significantly over the past 10 years. This is due to the increased demand for water bladders in the market, as well as the improved production processes and technology used by Chinese manufacturers. In addition, the Chinese government has also provided incentives to manufacturers to increase their production capacity and efficiency. As a result, the production profit of Chinese water bladder manufacturers has grown steadily over the past 10 years.

water bladder manufacturer production process management

1. Establish a production plan: Establish a production plan that outlines the production process, including the materials, equipment, and personnel needed to complete the process.

2. Establish quality control standards: Establish quality control standards for the production process, including the materials, equipment, and personnel used.

3. Monitor production process: Monitor the production process to ensure that it is being carried out according to the established plan and quality control standards.

4. Track production data: Track production data, such as the number of units produced, the time it takes to complete each step of the process, and the quality of the finished product.

5. Make adjustments: Make adjustments to the production process as needed to ensure that the quality of the finished product meets the established standards.

6. Document changes: Document any changes made to the production process and the reasons for making them.

7. Train personnel: Train personnel on the production process and quality control standards.

8. Evaluate performance: Evaluate the performance of personnel and the production process to ensure that it is meeting the established standards.

The production of water bladder manufacturer needs to meet the following environmental protection conditions

1. Adhere to the principle of environmental protection and energy conservation, and reduce the emission of pollutants.

2. Use clean production technology and equipment to reduce the emission of pollutants.

3. Strictly control the emission of pollutants and strictly abide by the environmental protection laws and regulations.

4. Establish a sound environmental management system and implement it.

5. Strengthen environmental protection education and training for employees.

6. Strengthen environmental protection supervision and inspection, and timely rectify environmental pollution.

7. Establish a sound environmental protection emergency response system.

8. Strengthen environmental protection publicity and education, and promote the concept of green production.

The production process of the water bladder manufacturer

1. Design: The first step in the production process of a water bladder manufacturer is to design the product. This includes creating a prototype, selecting the materials, and determining the size and shape of the bladder.

2. Manufacturing: Once the design is finalized, the manufacturer will begin the manufacturing process. This includes cutting the material, welding the seams, and attaching the valves and other components.

3. Testing: After the bladder is manufactured, it is tested for quality and durability. This includes pressure testing, leak testing, and other tests to ensure the product meets the manufacturer’s standards.

4. Packaging: Once the bladder passes all tests, it is packaged for shipment. This includes labeling, boxing, and other packaging steps.

5. Shipping: The bladder is then shipped to the customer.

Compared with 10 years ago, the manufacturing process of water bladder manufacturer has the following improvements

1. Automation: Automation has been widely adopted in the manufacturing process of water bladder manufacturers, allowing for faster and more efficient production.

2. Quality Control: Quality control has been improved significantly, with more stringent standards and better testing methods.

3. Materials: New materials have been developed that are more durable and resistant to wear and tear.

4. Technology: Advanced technologies such as 3D printing and laser cutting have been adopted to improve the accuracy and speed of production.

5. Cost Reduction: The cost of production has been reduced significantly due to the use of automation and improved materials.

6. Safety: Safety standards have been improved to ensure the safety of workers and the environment.

The introduction of the latest production technology can make a water bladder manufacturer more profitable

The introduction of the latest production technology can make a water bladder manufacturer more profitable by increasing efficiency, reducing costs, and improving product quality. By investing in the latest production technology, a water bladder manufacturer can reduce labor costs, increase production speed, and improve product quality. This can lead to increased profits as the manufacturer can produce more products in a shorter amount of time and at a lower cost. Additionally, the improved product quality can lead to increased customer satisfaction and more repeat customers.

Three plans for water bladder manufacturers to improve production efficiency

1. Automate Production Processes: Automating production processes can help water bladder manufacturers reduce labor costs and increase production efficiency. Automation can also help reduce errors and improve product quality. Automation can be achieved through the use of robotics, computer-controlled machines, and other advanced technologies.

2. Implement Lean Manufacturing Practices: Lean manufacturing is a set of principles and practices that focus on eliminating waste and improving efficiency. Lean manufacturing can help water bladder manufacturers reduce costs, improve quality, and increase production speed.

3. Invest in Quality Control: Quality control is essential for any manufacturing process. Investing in quality control measures can help water bladder manufacturers ensure that their products meet customer expectations and industry standards. Quality control measures can include testing, inspections, and audits.

Analysis of the cost that the water bladder manufacturer pays for the implementation of new product research and development every year

The cost of implementing new product research and development for a water bladder manufacturer will vary depending on the size and scope of the project. Generally, the cost of research and development for a new product can range from a few thousand dollars to hundreds of thousands of dollars. The cost will depend on the complexity of the product, the number of prototypes needed, the number of tests required, and the amount of time and resources needed to complete the project. Additionally, the cost of research and development may also include the cost of materials, labor, and other overhead costs.

water bladder manufacturer service and quality system

A water bladder manufacturer should have a quality system in place to ensure that their products meet the highest standards of safety and performance. This system should include a comprehensive set of procedures and processes to ensure that all products are manufactured to the highest quality standards. The system should include a quality assurance program, a quality control program, and a quality management system. The quality assurance program should include a system of checks and balances to ensure that all products meet the required specifications. The quality control program should include a system of inspections and tests to ensure that all products meet the required standards. The quality management system should include a system of documentation and records to ensure that all products are manufactured to the highest quality standards.

water bladder manufacturer need to observe the following 5 points to establish a sound supply chain management

1. Establish a clear supply chain strategy: A clear supply chain strategy should be established to ensure that the manufacturer is able to meet customer needs and expectations. This should include a plan for sourcing, production, distribution, and customer service.

2. Develop strong relationships with suppliers: Developing strong relationships with suppliers is essential for a successful supply chain. This includes understanding the supplier’s capabilities, negotiating favorable terms, and ensuring that the supplier is able to meet the manufacturer’s needs.

3. Utilize technology: Technology can be used to streamline the supply chain process and improve efficiency. This includes using software to track inventory, manage orders, and monitor supplier performance.

4. Monitor performance: It is important to monitor the performance of the supply chain to ensure that it is meeting customer needs and expectations. This includes tracking delivery times, order accuracy, and customer satisfaction.

5. Continuously improve: The supply chain should be continuously improved to ensure that it is meeting customer needs and expectations. This includes making changes to processes, implementing new technologies, and developing new strategies.

What are the services of water bladder manufacturer?

Water bladder manufacturers typically provide a range of services, including custom design and fabrication of water bladders, installation and maintenance of water bladders, and repair and replacement of water bladders. They may also provide consulting services to help customers select the best water bladder for their needs. Additionally, some water bladder manufacturers may offer additional services such as water testing and filtration, water storage tank installation, and water delivery services.

R&D direction of water bladder manufacturer industry

1. Developing new materials: Developing new materials for water bladder manufacturing that are more durable, lightweight, and cost-effective.

2. Automation: Developing automated production processes to reduce labor costs and improve efficiency.

3. Design: Developing innovative designs for water bladders that are more ergonomic and aesthetically pleasing.

4. Quality control: Developing quality control systems to ensure that water bladders meet safety and performance standards.

5. Recycling: Developing methods for recycling used water bladders to reduce waste and environmental impact.

6. Technology: Developing new technologies to improve the performance and efficiency of water bladders.

7. Marketing: Developing effective marketing strategies to increase brand awareness and sales.

How to improve the quality of water bladder manufacturers

1. Invest in high-quality materials: Investing in high-quality materials is essential for producing quality water bladders. Look for materials that are durable, lightweight, and resistant to punctures and tears.

2. Utilize advanced manufacturing techniques: Utilizing advanced manufacturing techniques such as injection molding and rotational molding can help to ensure that the water bladders are of the highest quality.

3. Implement quality control measures: Quality control measures should be implemented throughout the manufacturing process to ensure that the water bladders meet the highest standards of quality.

4. Provide customer service: Providing excellent customer service is essential for ensuring customer satisfaction. Make sure that customers can easily contact the manufacturer with any questions or concerns they may have.

5. Offer warranties: Offering warranties on the water bladders can help to ensure that customers are satisfied with their purchase.

Customer group and service level of water bladder manufacturer

The customer group for a water bladder manufacturer would likely include outdoor enthusiasts, athletes, and military personnel. The service level of the manufacturer would depend on the specific product and services offered. Generally, the service level would include product customization, quality assurance, and customer service.

After-sales compensation terms for water bladder manufacturer

1. Warranty: The water bladder manufacturer should provide a warranty for all products sold. The warranty should cover any defects in materials or workmanship for a period of at least one year from the date of purchase.

2. Replacement: The water bladder manufacturer should provide a replacement for any product that fails to meet the manufacturer’s specifications within the warranty period.

3. Refund: The water bladder manufacturer should provide a full refund for any product that fails to meet the manufacturer’s specifications within the warranty period.

4. Repair: The water bladder manufacturer should provide repair services for any product that fails to meet the manufacturer’s specifications within the warranty period.

5. Shipping: The water bladder manufacturer should provide free shipping for any product that needs to be returned for repair or replacement.

6. Customer Service: The water bladder manufacturer should provide prompt and courteous customer service to address any questions or concerns about the product.

water bladder manufacturer need to pay attention to the following 6 points when establishing their own water bladder dealer channels

1. Establish a good relationship with the dealer: Establishing a good relationship with the dealer is the key to success in establishing a water bladder dealer channel. The manufacturer should communicate with the dealer regularly, understand the dealer's needs, and provide the dealer with the necessary support.

2. Develop a comprehensive marketing plan: Develop a comprehensive marketing plan to ensure that the dealer can effectively promote the water bladder products. The plan should include promotional activities, advertising, and other activities to help the dealer increase sales.

3. Provide training to the dealer: Provide training to the dealer to ensure that they understand the features and benefits of the water bladder products. This will help the dealer to better promote the products and increase sales.

4. Offer incentives to the dealer: Offer incentives to the dealer to encourage them to promote the water bladder products. This could include discounts, free samples, or other rewards.

5. Monitor the performance of the dealer: Monitor the performance of the dealer to ensure that they are meeting the goals set by the manufacturer. This will help the manufacturer to identify areas where the dealer needs to improve and provide the necessary support.

6. Provide feedback to the dealer: Provide feedback to the dealer to ensure that they are satisfied with the products and services provided by the manufacturer. This will help the manufacturer to build a strong relationship with the dealer and ensure that the dealer is motivated to promote the water bladder products.

water bladder manufacturer are more worthy of cooperation if they have patents

Yes, water bladder manufacturers with patents are more worthy of cooperation because they have invested in research and development to create a unique product. Patents provide legal protection for the manufacturer's intellectual property, which can help them to protect their market share and increase their profits. Additionally, patents can also help to differentiate the manufacturer's product from competitors, which can help to attract more customers.

Product quality control of water bladder manufacturer

1. Establish a quality control system: Establish a quality control system that includes a set of procedures and processes to ensure that the water bladder manufacturer is producing products that meet the required standards.

2. Inspect raw materials: Inspect all raw materials used in the production of water bladders to ensure they meet the required standards.

3. Test the product: Test the water bladders for any defects or inconsistencies in quality.

4. Monitor production process: Monitor the production process to ensure that the water bladders are being produced according to the required standards.

5. Document results: Document the results of all quality control tests and inspections.

6. Take corrective action: Take corrective action if any defects or inconsistencies are found in the water bladders.

7. Train employees: Train employees on the quality control system and procedures.

8. Regularly review quality control system: Regularly review the quality control system to ensure it is up to date and effective.

The international production mode adopted by water bladder manufacturers

Water bladder manufacturers typically use an international production mode that involves outsourcing production to countries with lower labor costs. This allows them to reduce their production costs and increase their profits. The production process typically involves the manufacture of the bladders in the country of origin, followed by the assembly of the bladders in the destination country. This allows the manufacturer to take advantage of the lower labor costs in the country of origin while still maintaining quality control in the destination country.

What services are included in the water bladder manufacturer's after-sales service?

The after-sales service of a water bladder manufacturer typically includes product installation, maintenance, repair, and replacement services. They may also offer technical support and customer service to help customers with any questions or concerns they may have. Additionally, some manufacturers may offer warranties on their products to ensure customer satisfaction.

What is water bladder design?

Water bladder design is a type of water storage system that uses a flexible, airtight bladder to store water. The bladder is typically made of a durable material such as rubber or plastic and is designed to hold a specific amount of water. The bladder is then placed inside a larger container, such as a tank or cistern, and connected to a water supply. This allows for easy access to the stored water and helps to keep it clean and safe for use.

water bladder design, comparison of advantages and disadvantages of Chinese and American design levels

Chinese Design Level

Advantages:

• Low cost of production due to the availability of cheap labor and materials.

• Lightweight and durable materials used in the construction of the bladder.

• Easy to transport and store due to its compact size.

• Can be used in a variety of climates and conditions.

Disadvantages:

• Quality control may be lacking due to the lack of stringent regulations.

• May not be as durable as American-made bladders due to the use of lower quality materials.

• May not be as reliable in extreme temperatures or conditions.

American Design Level

Advantages:

• High quality materials used in the construction of the bladder.

• Strict quality control regulations ensure a reliable product.

• Durable and reliable in extreme temperatures and conditions.

• Easy to transport and store due to its compact size.

Disadvantages:

• Higher cost of production due to the use of higher quality materials.

• May be heavier than Chinese-made bladders due to the use of higher quality materials.

water bladder manufacturer' skill requirements for production operators

Production operators in a water bladder manufacturer must have a variety of skills and abilities in order to be successful.

• Knowledge of the manufacturing process and the ability to read and interpret blueprints and technical drawings.

• Ability to use hand and power tools, as well as other machinery, to assemble and fabricate components.

• Knowledge of safety protocols and the ability to follow safety procedures.

• Ability to work with a variety of materials, including plastics, rubber, and metal.

• Ability to use measuring instruments and gauges to ensure accuracy of product dimensions.

• Ability to troubleshoot and identify problems with machinery and equipment.

• Ability to work in a fast-paced environment and meet production deadlines.

• Ability to work independently and as part of a team.

• Ability to lift and move heavy objects.

• Ability to stand for long periods of time.

• Ability to work in a variety of temperatures and conditions.

water bladder design, what are the shortcomings of Chinese enterprises?

1. Lack of innovation: Chinese enterprises often lack the ability to innovate and develop new products.

2. Poor quality control: Chinese enterprises often lack the necessary quality control measures to ensure the safety and reliability of their products.

3. Limited resources: Chinese enterprises often lack the resources to invest in research and development, which can limit their ability to develop new products.

4. Limited access to international markets: Chinese enterprises often lack the necessary resources and connections to access international markets.

5. Poor customer service: Chinese enterprises often lack the necessary customer service infrastructure to provide adequate support to their customers.

Effect drawing of water bladder design

A water bladder design is a type of container that is used to store and transport water. It is typically made of a flexible material such as rubber or plastic and is designed to be filled with water and then sealed. The drawing below shows a simplified version of a water bladder design. The bladder is made up of two layers of material, with a valve at the top for filling and draining. The bladder is also equipped with straps for carrying and a handle for easy transport.

About the brand of the water bladder manufacturer

The water bladder manufacturer is called Hydrapak. Hydrapak is a leading manufacturer of hydration solutions for outdoor and active lifestyles. They specialize in creating innovative, high-performance hydration products that are designed to meet the needs of athletes, adventurers, and outdoor enthusiasts. Their products include water bladders, hydration packs, hydration reservoirs, and accessories. Hydrapak is committed to providing quality products that are designed to last and perform in any environment.

Classification of water bladder design styles

1. Collapsible: These water bladders are designed to be folded or rolled up when not in use, making them easy to store and transport.

2. Rigid: These water bladders are designed to be rigid and are usually made of hard plastic or metal. They are more durable than collapsible bladders, but are not as easy to store or transport.

3. Hydration Pack: These water bladders are designed to be worn on the back and are usually made of lightweight materials. They are designed to be comfortable and provide easy access to water while on the go.

4. Insulated: These water bladders are designed to keep water cold for extended periods of time. They are usually made of insulated materials and are great for outdoor activities.

5. Gravity-Fed: These water bladders are designed to be hung from a tree or other elevated structure and use gravity to dispense water. They are great for camping and other outdoor activities.

Skill requirements for designers

1. Knowledge of design principles and techniques: Designers should have a strong understanding of design principles such as composition, color theory, typography, and layout.

2. Knowledge of software: Designers should be proficient in the use of design software such as Adobe Photoshop, Illustrator, InDesign, and other related programs.

3. Creativity: Designers should be able to think outside the box and come up with creative solutions to design problems.

4. Communication skills: Designers should be able to communicate their ideas effectively to clients and colleagues.

5. Attention to detail: Designers should be able to pay attention to details and ensure that their designs are accurate and consistent.

6. Time management: Designers should be able to manage their time effectively and meet deadlines.

7. Problem-solving skills: Designers should be able to identify problems and come up with solutions.

Top ten international water bladder brands

1. Platypus

2. CamelBak

3. Geigerrig

4. Hydrapak

5. Source Outdoor

6. Osprey

7. MSR

8. Nalgene

9. Vapur

10. Hydration Depot

Analysis of the competition trend of China's water bladder market

The water bladder market in China has seen a steady growth in recent years. This is due to the increasing demand for water bladders from consumers, as well as the growing popularity of outdoor activities such as camping and hiking.

The competition in the Chinese water bladder market is becoming increasingly fierce. This is due to the entry of new players into the market, as well as the increasing number of existing players. The competition is also driven by the increasing number of innovative products being introduced into the market.

In terms of pricing, the competition in the Chinese water bladder market is becoming increasingly intense. This is due to the fact that the cost of production is increasing, as well as the fact that the market is becoming increasingly saturated. As a result, companies are forced to reduce their prices in order to remain competitive.

In terms of product quality, the competition in the Chinese water bladder market is also becoming increasingly intense. This is due to the fact that consumers are becoming increasingly aware of the importance of quality when it comes to water bladders. As a result, companies are forced to invest in research and development in order to produce high-quality products.

Overall, the competition in the Chinese water bladder market is becoming increasingly intense. This is due to the increasing demand for water bladders from consumers, as well as the increasing number of players in the market. Companies must invest in research and development in order to remain competitive and produce high-quality products.